Placed in our assembly department are presently two big frame cranes, which, however, are going to be used for very different purposes.

The blue frame crane is going to be installed at Essity Hygiene And Health of Sweden. Pallets with products (packs of kitchen rolls and toilet paper etc.) are coming in from Essitys’ other factories for storage in their high bay warehouse before shipment to the customers.

The problem is that some of the pallets are too high for storage in the warehouse and need to be reduced in height. It’s here the frame crane comes in. The crane will automatically cut the pallet foil wrap in a certain height whereupon the crane will grab hold of the content above the cut foil and place it on another pallet.

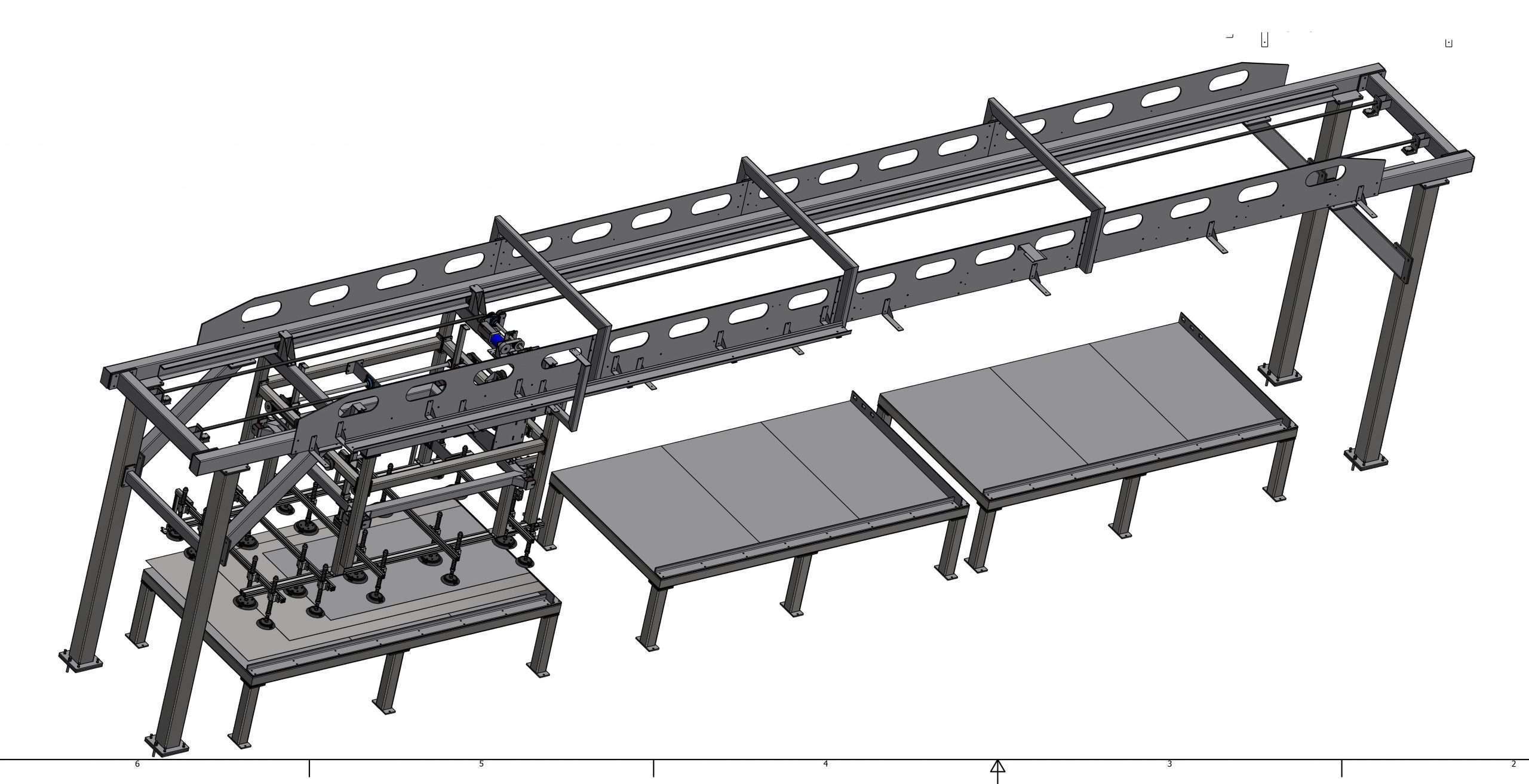

The red crane is going to be installed at Inox Steel, a Danish distributor of stainless steel. The purpose of the frame crane is to streamline the execution of orders and to improve the working environment through automation.

When the truck driver starts picking a new order, which can comprise more different types of sheet steel, he will fetch 2 pallets with a stack of sheets and place the pallets on each of the two tables.

Now the crane will pick up one sheet at a time using suction cups and place them on the outfeed conveyor; first the ordered quantity from one pallet and then from the second pallet. If the customer has ordered more types of sheet steel the two pallets will be brought back to the storeroom and the next pallets will be placed on the table(s).

The pallet will then be strapped and taken to the shipping dept.

There are paper sheets between the steel sheets in the storeroom. This paper must be removed and therefore, the frame crane is equipped with air nozzles which will blow away the paper before the sheet steel is picked up and placed on the “order pallet”.

Both frame cranes are going to be finished before the end of 2019.

The drawing shows the red crane for Inox Steel.